Published in the June 2013 issue of “Die Porsche Kassette”

If your car’s suspension creaks, squeals and grunts like the famous 1930 Wramblin’ Wreck Ford from Georgia Tech (Go Jackets!) when you go over a bump or when turning the wheel, it’s probably just a dried out (ball) joint in one of its suspension components.

So, just replace the component, right?

Well ... maybe there’s something else you can do to extend the life of the part, save some money but more importantly: Quiet down the creaking!

On the newer Porsches there are

no lube points in the suspension

as in the old (‘70s) cars.

The ball joints

come

with a

“lifetime

lubrication”

which comes well short of the car’s life.

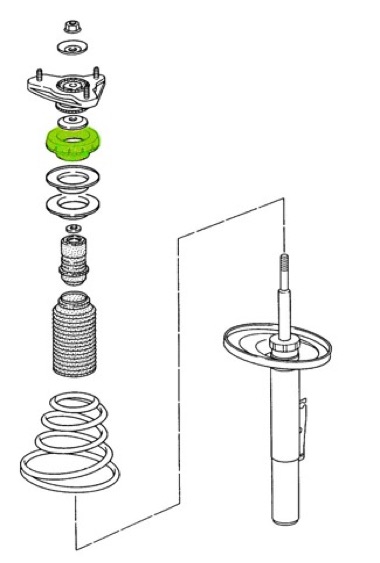

These components with ball joints, such as: control arms, trailing arms, wishbones, anti-sway bar droplinks, etc. are quite extensive and expensive and replacing them will generally also require an alignment since the suspension geometry will change with the installation of the new part. For instance, here are the components on one the rear corners. The front has similar parts as well.

I’ve highlighted the components with ball joints.

The ball joint itself is generally protected by a rubber boot (dust cover) which can deteriorate with time or can be damaged by debris or by the improper use of tools, then the tear in the boot allows the grease to dry up quicker and the creaking begins.

Even without any damage to the boot, when the “lifetime” grease in these ball joints starts to dry out your car will let you know with very loud and embarrassing creaking.

If you don’t want to replace the component(s) you can fix it quickly and inexpensively yourself.

All you need to do is put some quality grease back into the joint. You can do this without removing any parts.

If the boot is torn you’ll also need to reseal the tear with silicone sealant or similar after you repack with grease.

To have access to these components you just need to jack up the offending corner and remove the wheel.

You will be able to access the wishbone and track arm ball joints which are the main culprits (highlighted in yellow).

The control arm (highlighted in red) needs to be accessed from underneath the car, but this joint generally lasts a lot longer than the others and when it wears, it doesn’t creak or squeal, it clunks and rattles when going over rough terrain.

To take care of these issues yourself, with very little money, purchase a mini grease gun with a needle adapter which is made for this purpose. You can get it at most auto parts stores. The needle makes such a small hole in the rubber boot that it seals itself after greasing without the need for silicone or glue.

Use a good quality “moly” grease.

Inject grease until it starts to ooze out of the boot.

That’s it. Cured!

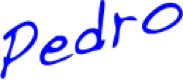

But if the groaning is due to the turning of the steering wheel, then most likely the issue is in the upper strut bearing (highlighted in green).

This is not a sealed bearing so it collects dust and grime with mileage. If not cleaned and repacked it will eventually lead to bearing damage.

The cure for this one is much more involved than that of the simple injection of grease, as explained above.

This bearing needs to be removed, cleaned and repacked with grease. After it is reassembled, an alignment needs to be performed because the strut has to be removed to allow access to the bearing.

Once the strut is moved, the alignment is off, so it has to be reset.

Generally these creaking sounds start to appear at around 100,000 miles and once they start they will get worse until fixed.

Avoid the temptation of trying to squirt a little WD-40 into the joint as a quick way to cure it. Contrary to popular belief, WD-40 is not a lubricant!

WD stands for Water Displacement, and was developed to dry-out components, not to lubricate them.

This fix works! I guarantee it!

When my car started to sound like the Ramblin’ Wreck from Georgia Tech, I did what I described above and it immediately quieted down my ride.

That was some years ago with 110,000 miles on the odometer.

I must admit that I had to repeat the procedure once more, last week, but now with the odometer showing 231,000 miles.

To learn more about the suspension in your car, please visit my website at: wwwPedrosGarage.com.

Happy Porscheing,

Ⓒ2013 Technolab / PedrosGarage.com