Published in the June 2012 issue of “Die Porsche Kassette”

... together with “Kokomo” and “Help Me Rhonda” they are my top 3 Beach Boys songs... but I digress.

I really want to hear some good vibrations coming from my 1998 Boxster’s M96 engine, not just through my car’s iPod. Soon, I may just be able to do that.

I’m sure you’ve read about the catastrophic failures involving IMS bearings, timing chains, D-chunks and more on the Porsche M96/M97 engines, but what if I told you that you can now see (actually hear) inside your engine with what one Porsche enthusiast soon hopes will be a small, inexpensive listening device to capture your engine’s vibrations!

That enthusiast is Mark Jennings from Inland Northwest Region PCA.

Mark has been a PCA member since 1989 and today he drives a 2002 Carrera 996 which he bought new.

Professionally, Mark is a consulting engineer who specializes in Industrial Equipment Vibration Analysis. He is a recognized expert in this subject and works with the US Department of Energy operating contractors and commercial nuclear clients in the Pacific Northwest on rotating equipment vibration and balance issues. Mark also provides vibration monitoring, analysis and training to a broad list of commercial clients. Mark looks at pumps, fans, compressors, motors, generators, turbines, gear drives, diesels and many other pieces of equipment that rotate and that have the potential to self-destruct due to balance, alignment or high vibration issues.

However, in the past year or so, Mark has been busy collecting and analyzing vibration data on Porsche M96 and M97 engines using industrial analysis equipment and applying standard protocol monitoring techniques.

What that means to owners of Boxsters, Caymans and Carreras that utilize these engines, is a quick way to determine if there is a cam chain, a primary chain an IMS bearing or even ignition issues associated with their cars with no disassembly required.

This vibration analysis is the first in non-intrusive, preventive service ever done on these engines.

Imagine being able to "see", or actually "hear", inside your engine and determine that one of your timing chains is a bit too loose or that the IMS bearing has started to fail, or even better, to get a clean bill of health because your car has a healthy engine and you can see those good vibrations!

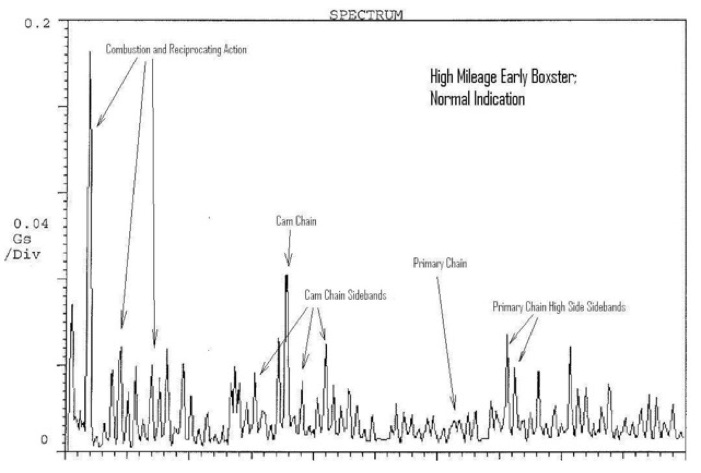

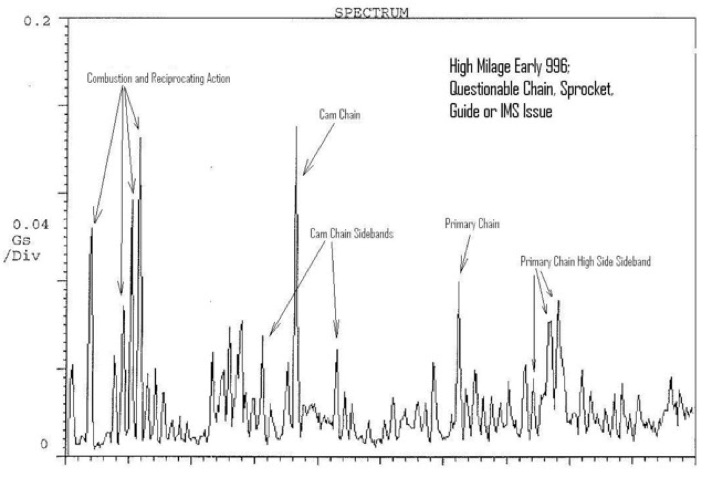

Mark uses a portable, digital vibration analyzer which is basically an oscilloscope that shows an alternating (AC) signal from an accelerometer. The AC signal is broken down by the analyzer into a frequency spectrum through the use of complex mathematical integrations. This provides a snapshot of the frequency peaks created by the components inside the engine. Mark says that “if there is something that bumps, clicks, rubs, pounds or pulses in a periodic manner” he can see it. Based on its frequency Mark can identify the component and based on the amplitude of the signal he can tell how bad it is.

The data collecting procedure is very quick and easy. First, a small accelerometer is secured with a bolt to the bottom of the M96/M97 engine using an existing threaded hole on the engine block, then the car is taken for a drive, setting the cruise control at a specific RPM until the data collection cycle is complete, generally about 60 seconds.

Finally the gizmo gets removed from the car and its data is analyzed. The newly obtained data graphs are then compared with those of a “normal” engine of the same model.

This year Mark will be collecting and analyzing more data from these engines by attending Porsche gatherings and Tech Sessions in the Pacific Northwest and other regions.

To help him in his endeavor, the Planers of the Blue Ridge Boxster Summit 2012 which will be held in Little Switzerland, NC, have invited him to attend our 15th gathering in early June, where he will attach his “black box” to approximately 60 Porsches including Boxsters, Caymans and Carreras all with the M96/M97 engine. If you want to be one of the lucky ones who gets to hear your engine’s good vibrations, be sure to attend this event. Information at www.BRBS.org.

Hopefully, Mark can quickly finish his “listening device” which he wants small shops, PCA Regions and DIY’ers to have, to be able to complete a simple go/no-go test of their cars. Mark has said that “eventually, if we can collect enough data to show the technology and application is appropriate, we could as an owners group, convince Porsche Cars North America (PCNA) to invest in the technology and training so that cars in for routine service could be spot checked and evaluated for timing chains, tensioners, sprockets and of course, intermediate shaft bearing issues”.

If you’d like a more in-depth and technical reading of Mark’s technology you can read his “996 Engine Vibration Tech Session” which was published in the March – April 2012 issue of NWR’s newsletter: Über Alles.

To learn of Marks findings and more, please visit my website at: www.Pedrosgarage.com.

Good Vibrations and Happy Porscheing,

Ⓒ2012 Technolab / PedrosGarage.com