Published in the June 2015 issue of “Die Porsche Kassette”

Big cross-drilled brake rotors which fill the inside space of the wheels look sexy and racy but, are they the best option?

Let’s take a look back to the first cross-drilled rotors and why they were left full of holes.

Back in the 60s, when the first disc brakes started appearing on production vehicles and therefore on race cars, it was quickly discovered that when the brakes were applied forcefully (as in a racecar) the brake pad material would sublime (go directly from solid to gas).

This would create a cushion of gas between the rotor and the pad that gave a brief loss-of-brakes before the pads again grabbed.

Engineers soon realized that if they cross-drilled the rotors and even better, if they vented the rotors and then cross-drilled them the gasses would immediately have a route to escape and the brakes would feel strong and progressive from the onset, hence the use of cross-drilling on racecars began.

Since in those days it was “Win on Sunday & Sell on Monday” these cross-drilled rotors began to appear on sports and high performance cars as well. Very soon it became the norm that a sports car should have cross-drilled disc brakes and this created the idea that cross-drilled rotors offer increased breaking performance.

Today, with advances in metallurgy (rotors) and materials science (pads) there is no need for cross-drilled rotors anymore, but we keep seeing them in our Porsches, Lamborghinis and Ferraris. Why? Because car buyers think they look cool.

You’re thinking: “That can’t be, Pedro has lost his marbles”, but I can assure you that that’s the case.

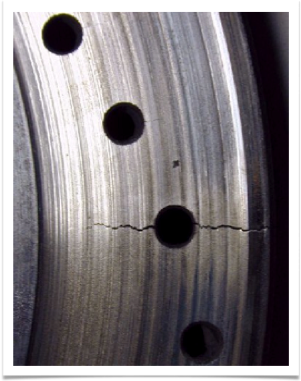

Take a good look at any serious professional racecar today. I bet you won’t see any cross-drilled rotors and that’s because they create more problems than they solve. What all those holes do in a rotor is create stress points and a rotor surface that’s heated and cooled unevenly. This results in rotors that can easily crack and makes catastrophic brake failure more likely. The worst case is when cracks between multiple holes connect, which can lead to a large chunk of rotor breaking free. Not a pretty sight.

Technically, a blank rotor will offer the best braking performance because the brake pads of today don’t sublime like in the old days.

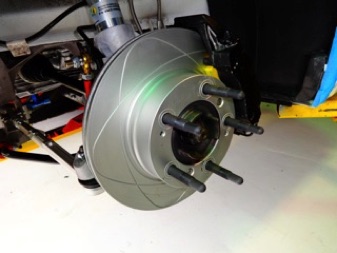

But, when running in the rain, the water on the pad’s or rotor’s surface will turn to vapor as soon as the two surfaces meet, having the same effect as the old sublimation, so what you will see in most top-notch racecars today are slotted rotors.

Slotting serves the same purpose as cross-drilling (letting gasses escape) without weakening the rotor as much.

If you track your car and have cross-drilled rotors, go and look at them closely and I bet you you’ll find some surface stress fractures.

And the next time you’re at the track and a car comes into the paddock from doing hot laps with cross-drilled rotors, go and put your ear next to one of the front wheels and you’ll likely hear metallic pings, clicks and pops as the rotor’s surface cools unevenly.

What you ware hearing is in essence cracks forming!

Cross-drilled rotors may look cool, but they’re not the best option because ...

... they’re full of holes!

For more information on brakes and more, please visit my website: www PedrosGarage.com.

Happy Porsche’ing,

Ⓒ2015 Technolab / PedrosGarage.com